PrintLamB2S

The fastest and most user-friendly automatic B2 laminating machine

Main reasons to choose a TAULER PrintLamB2S:

- Because it incorporates the TAULER_OIL system that improves lamination and reduces energy consumption.

- Because it incorporates a quick coil adjustment feature while the machine is running.

- Because it incorporates the TAULER_SHAFT SYSTEM that facilitates the quick change of film.

- For its intuitive touch screen.

- Because it incorporates a REVERSE MODE to correct possible errors.

- Because it incorporates TAULER_GO ON, an automatic starting system.

Technical details:

- Automatic feeding.

- Adjustable side bracket.

- Temperature control by sensor.

- Pneumatic pressure roller.

- Easily adjustable decurling system.

- Photocell that stops the machine in case of sheet failure.

- Total control of the machine through a PLC.

- Electronically adjustable speed.

- Microperforation cutting system and scissor roller.

- Optional stacker.

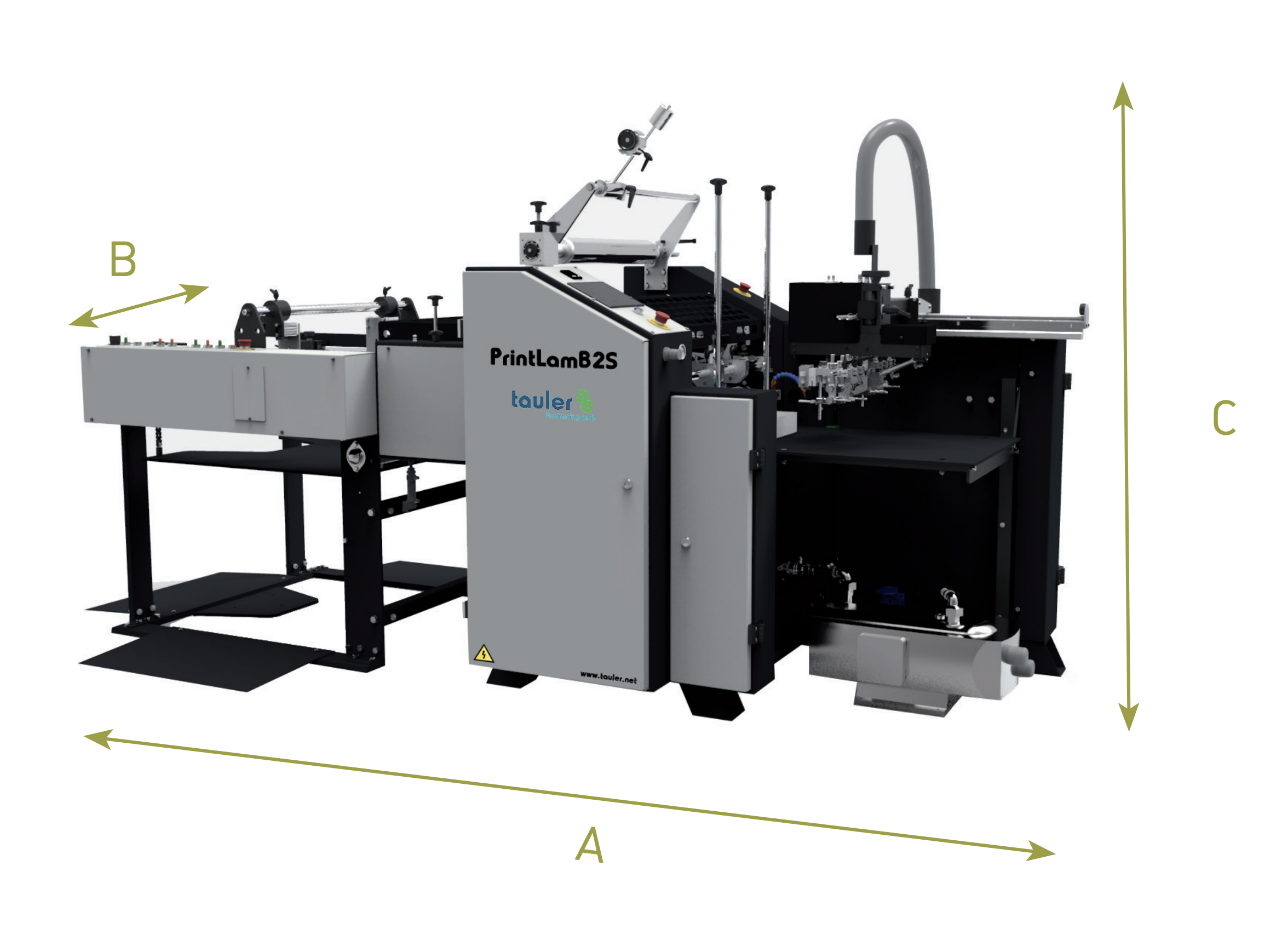

Maximum length [A]: 270 cm

Maximum width [B]: 125 cm

Maximum height [C]: 170 cm

Pes: 1.000 kg

Technical details

| Maximum format | 520×740 mm |

| Minimum format | 220×250 mm |

| Maximum mechanical speed | 2 – 35 m/min* |

| Paper thickness | 130 to 450 g/m2 |

| input/Output stack height | 530 mm |

| Film thickness | 20 to 42 μm |

| Electrical power installed | 9 kW |

| Power supply | 400 V three-phase 50 Hz |

| Security | CE-compliant protections, emergency stops, and safety sensors. |

*According to film, external conditions, paper type, thickness, and formats.

TAULER reserves the right to modify the characteristics of this product without prior notice. The image shown and the information reflected in this web & brochure does not establish contractual information. TAULER AND PRINTLAM ARE REGISTRED TRADEMARKS OF TAULER LAMINATING TECH, SL

Contact Form

"*" indicates required fields